The floors do not chip off from the corners and you don't see any scratches. It will become the foundation for a lot of places. You'll find a great deal of epoxy floor paints that may be bought from hardware stores but a lot of these simply have a number of directions on how to mix it. Epoxy flooring is actually the process of applying stratum of epoxy resin during a floor's surface, often up to 2 mm thick.

Images about Glass Cast Epoxy Resin For Floors

Glass Cast Epoxy Resin For Floors

Epoxy flooring coating is a flooring surface made up of several stratum of epoxy applied to the floor to a level of less than two millimeters. Epoxy seamless is actually a great idea for industrial workshop, garage and also for kid's bedroom flooring to go over flat, gray concrete and present you with protected, appealing, easy to surfaces which are clean.

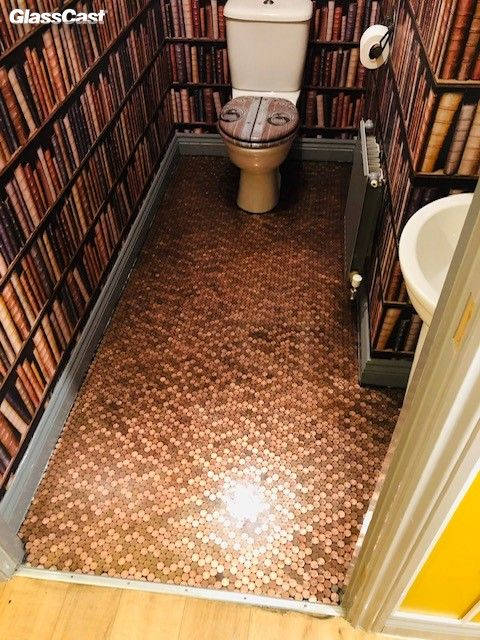

GlassCast 3 Penny Floor Epoxy Resin – GlassCast

This's precisely why, when it comes to renovating you floor surfaces, you should put in epoxy flooring. Therefore to be exact, epoxy resins have fairly limitless uses & benefits. Thus, if you are into redefining garage or perhaps warehouse flooring, try out epoxy coating for traditional pro appeal to the floor. Therefore, you will need to remove a polyurethane or perhaps latex floor before using epoxy.

GlassCast® 3 Clear Epoxy Penny Floor Resin, Tabletop, Bar-Top Coating Resin eBay

GlassCast 10 Clear Resin for Crafts, Jewellery, and Art – GlassCast

GlassCast 3 Resin for Floors, Bar-tops and Coatings – GlassCast

EP-GC-1 Clear epoxy, Clear casting resin, Epoxy

GlassCast 3 Epoxy Resin u2013 MrResin

How to Lay a Penny Floor with GlassCast 3 Clear Epoxy Resin – YouTube

GlassCast 3 Clear Epoxy Coating Resin – Easy Composites

GlassCast 3 Resin for Floors, Bar-tops and Coatings – GlassCast

GlassCast Clear Epoxy Resin – Penny Floor Tutorial

DIY Designer Epoxy Resin Floor : 7 Steps (with Pictures

GlassCast 3 Penny Floor Epoxy Resin – GlassCast

GlassCast 3 Penny Floor Epoxy Resin – GlassCast

Related Posts:

- Benefits Of Epoxy Flooring In Garage

- Professional Epoxy Garage Floor Cost

- Wattyl Garage Floor Epoxy

- Epoxy Patio Floor

- Epoxy Garage Floor Designs

- How To Epoxy Floor Paint

- How To Apply Flakes To Epoxy Floor

- Metallic Epoxy Floor Coating Kit

- Epoxy Floor Coating Self Leveling

- Pearl Metallic Epoxy Floor Coatings

Introduction

Glass cast epoxy resin for floors has been gaining in popularity as a floor coating option in recent years. This type of epoxy resin is a two-part liquid that is poured over a substrate and then allowed to cure. The result is a hard and durable surface that can be used in a variety of applications. Glass cast epoxy resin for floors is ideal for residential, commercial, and industrial applications as it provides superior protection against moisture, chemicals, and wear and tear. In this article, we will discuss the benefits of using glass cast epoxy resin for floors, how to prepare the substrate and apply the resin, and some frequently asked questions about glass cast epoxy resin for floors.

What Are The Benefits Of Glass Cast Epoxy Resin For Floors?

Glass cast epoxy resin for floors offers many advantages over traditional floor coatings such as paint or sealers. First, it provides superior protection against moisture, chemicals, and wear and tear. The epoxy coating forms a strong bond with the substrate, creating a waterproof barrier that resists damage from water and other liquids. Additionally, because of its strong adhesion properties, glass cast epoxy resin for floors can be used on substrates such as concrete, wood, tile, metal, and more.

In addition to its waterproofing capabilities, glass cast epoxy resin for floors is also highly resistant to abrasion and chemicals. This makes it an ideal choice for areas that are exposed to heavy foot traffic or harsh chemicals. The epoxy’s glossy finish also adds a decorative touch to any room while also providing additional protection against scratches and other impacts. Finally, glass cast epoxy resin for floors is easy to clean and maintain; it can simply be wiped down with a damp cloth or vacuumed with a brush attachment.

How To Prepare The Substrate And Apply The Resin?

Before applying glass cast epoxy resin for floors, it is important to prepare the substrate properly. The substrate should be clean and free of dirt and debris before any application of the resin. Additionally, the substrate should be dry; any moisture present could cause the resin to not adhere properly. Once the substrate has been cleaned and dried, it should be lightly sanded with 320-grit sandpaper to provide an even surface for the resin to adhere to.

Once the substrate is ready for application, the two parts of the glass cast epoxy resin should be mixed together according to the manufacturer’s instructions. Before pouring the mixture onto the substrate, it should be spread evenly with a squeegee or brush. It is important to pay special attention to corners and edges while applying the mixture in order to ensure full coverage. After application, the mixture should be allowed to cure according to manufacturer’s instructions before being walked on or exposed to other elements.

Frequently Asked Questions About Glass Cast Epoxy Resin For Floors

Q: How long does it take for glass cast epoxy resin to cure?

A: The curing time depends on several factors such as temperature and humidity levels in the room where the resin was applied. Generally speaking, glass cast epoxy resin takes approximately 24 hours to fully cure at room temperature (around 70 degrees Fahrenheit).

Q: Is glass cast epoxy resin slip-resistant?

A: Yes, glass cast epoxy resin is slip-resistant when applied correctly. However, it is important to pay special attention to corners and edges while applying the mixture in order to ensure full coverage of all surfaces that may be exposed to foot traffic. Additionally, it may be necessary to add anti-slip additives during application in order to increase slip-resistance on surfaces that may become wet during use such as bathrooms or kitchens.

Q: Is glass cast epoxy resin difficult to clean?

A: No, glass cast epoxy resin is actually quite easy to clean; it can simply be wiped down with a damp cloth or vacuumed with a brush attachment. Additionally, it is highly resistant to stains from most common household spills such as food or beverages; even if these do manage to penetrate the surface of the coating they can usually be easily wiped away without leaving any residue behind.