Introduction to Concrete Floor Systems

Concrete floor systems are commonly used in construction projects due to their durability, strength, and versatility. They provide a solid and stable foundation for various structures, from residential homes to commercial buildings.

There are several types of concrete floor systems that are commonly used in construction. Each type offers unique characteristics and advantages, making them suitable for different applications. This comprehensive overview will provide insight into the different types of concrete floor systems commonly used in construction projects.

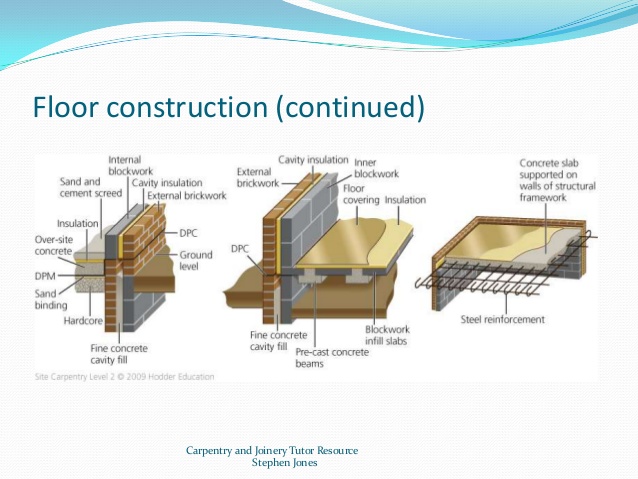

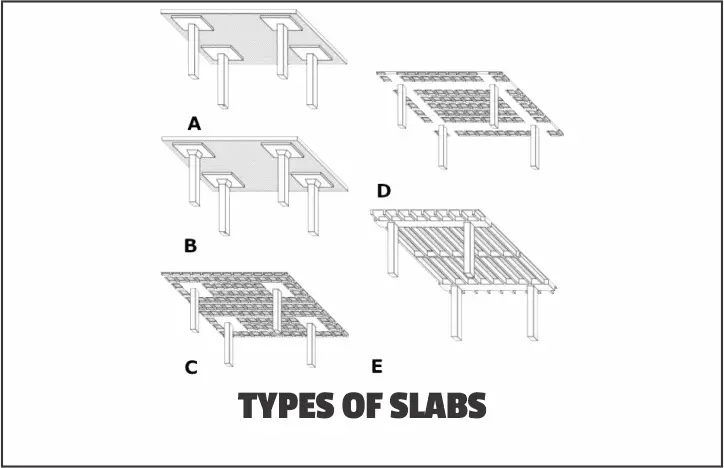

One of the most widely used types of concrete floor systems is the traditional slab-on-grade system. This system consists of a single layer of concrete poured directly onto the ground. It is commonly used in residential construction, where the ground conditions are stable and the load requirements are relatively low. Slab-on-grade systems are cost-effective and easy to construct, making them a popular choice for many projects.

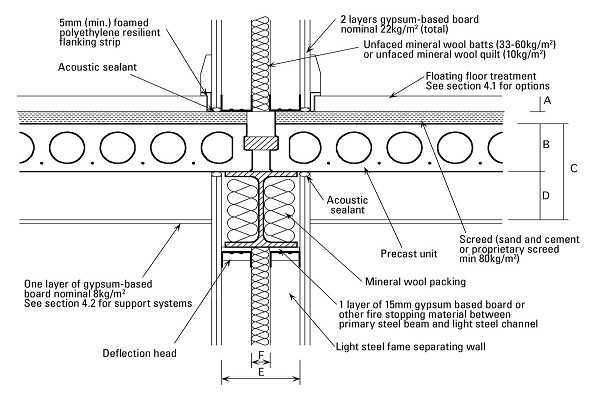

Another commonly used type is the suspended slab system. This system involves pouring concrete onto a supporting structure, such as beams or columns, creating a raised floor above the ground. Suspended slab systems are often used in commercial and industrial buildings, where higher load requirements and increased flexibility are necessary. They offer excellent sound and thermal insulation properties and allow for the installation of services, such as heating, ventilation, and electrical systems, below the floor.

In addition to these traditional systems, there are also precast concrete floor systems. Precast concrete panels or slabs are manufactured off-site and then transported to the construction site for installation. These systems offer several advantages, including faster construction time, improved quality control, and reduced site disruption. Precast concrete floor systems are commonly used in large-scale projects, such as parking garages and industrial facilities.

Furthermore, there are also composite concrete floor systems, which combine different materials to maximize their structural performance. One example is the composite steel deck system, which consists of a concrete slab poured onto a steel deck. This system offers the benefits of both concrete and steel, providing high strength and stiffness while minimizing the weight of the structure. Composite concrete floor systems are commonly used in multi-story buildings, where the combination of materials allows for longer spans and greater load capacities.

Traditional Concrete Slab

Traditional concrete slabs are one of the most commonly used types of concrete floor systems in construction. These slabs are known for their durability, versatility, and cost-effectiveness.

Durability is a key characteristic of traditional concrete slabs. They are designed to withstand heavy loads and provide long-lasting performance. This makes them suitable for a wide range of applications, including commercial and industrial buildings, warehouses, and residential structures. The durability of these slabs ensures that they can withstand the test of time, reducing the need for frequent repairs or replacements.

Versatility is another advantage of traditional concrete slabs. They can be customized to meet specific requirements and can be used in various settings. Whether it is a simple residential driveway or a complex industrial flooring system, traditional concrete slabs can be tailored to suit the needs of the project. Their versatility allows for different finishes, textures, and designs to be applied, providing options for aesthetic preferences.

Cost-effectiveness is a significant benefit of traditional concrete slabs. Compared to other flooring systems, such as wooden or tile floors, concrete slabs offer a more economical solution. The materials used for traditional concrete slabs are readily available and relatively inexpensive. Additionally, their long lifespan and low maintenance requirements contribute to overall cost savings over time.

Suspended Concrete Floors

There are several advantages and applications of suspended concrete floors, which are commonly used in high-rise buildings and industrial structures. These types of concrete floor systems offer numerous benefits, making them a popular choice in construction projects.

One of the main advantages of suspended concrete floors is their strength and durability. These floors are designed to support heavy loads, making them suitable for high-rise buildings and industrial structures where there is a need for additional strength and stability. The use of reinforced concrete in these floors enhances their load-bearing capacity, making them capable of supporting heavy machinery and equipment.

Another advantage of suspended concrete floors is their fire resistance. Concrete has excellent fire-resistant properties, which makes it an ideal material for constructing floors in buildings where fire safety is a concern. In the event of a fire, concrete floors can help contain the spread of flames and provide a safe escape route for occupants.

Suspended concrete floors also offer flexibility in terms of design and layout. They can be customized to suit specific requirements and can accommodate various architectural designs. This versatility allows for greater creativity and freedom in the design process, making suspended concrete floors a preferred choice for architects and designers.

Additionally, suspended concrete floors provide excellent sound insulation. The density and thickness of the concrete act as effective sound barriers, reducing noise transmission between different floors and rooms. This is especially beneficial in high-rise buildings and industrial structures, where noise control is essential for a comfortable working or living environment.

The applications of suspended concrete floors are extensive. In high-rise buildings, these floors are commonly used to provide stability, strength, and fire resistance. They are also utilized in industrial structures such as warehouses, factories, and manufacturing facilities, where heavy machinery and equipment are present. Suspended concrete floors are also used in commercial buildings, schools, hospitals, and other public structures where durability and safety are crucial.

Precast Concrete Flooring

Precast concrete flooring is a widely used construction material that offers numerous advantages in terms of efficiency, customization options, and suitability for large-scale construction projects. This section explores the characteristics and benefits of precast concrete flooring, shedding light on its various types and their specific applications.

Efficiency of Precast Concrete Flooring

One of the key advantages of precast concrete flooring is its inherent efficiency. Since precast concrete flooring is manufactured off-site in a controlled environment, it allows for improved quality control and faster construction timelines. The precast elements are produced in a factory setting, utilizing standardized processes and equipment, ensuring consistent quality and minimizing the risk of errors. This off-site production also reduces the time required for on-site construction, leading to significant time savings and increased project efficiency.

Customization Options

Precast concrete flooring offers a wide range of customization options, allowing architects and designers to achieve their desired aesthetic and functional requirements. The precast elements can be manufactured in various shapes, sizes, and finishes to suit specific project needs. Additionally, the use of different aggregates, colors, and textures provides endless design possibilities. Whether it is creating unique patterns, incorporating logos, or matching existing architectural elements, precast concrete flooring offers flexibility in design, enabling the realization of visually appealing and customized flooring solutions.

Suitability for Large-Scale Construction Projects

Precast concrete flooring is particularly suitable for large-scale construction projects due to its numerous advantages. The off-site manufacturing process ensures consistent quality control, leading to reliable and durable flooring systems. The efficiency gained from precast concrete flooring allows for faster construction, enabling the completion of projects within tight timelines. Moreover, the ability to customize precast elements to meet specific project requirements ensures a tailored solution that meets the demands of large-scale constructions. When it comes to high-rise buildings, infrastructure projects, or commercial developments, precast concrete flooring is a preferred choice due to its efficiency, reliability, and scalability.

Types of Economical Floor Systems for Reinforced Concrete Buildings

STRUCTURE magazine Creating an Opening in Existing Floors

6. Reinforced concrete slab types Download Scientific Diagram

Types of Economical Floor Systems for Reinforced Concrete Buildings

Concrete Floor Systems Dimensions u0026 Drawings Dimensions.com

Types of Slabs in Construction (20 Different Types)

Types of Floors for Multi-Storey Steel Structure Construction

Types of Concrete Floors u2014 Durable. Modern. Seamless.

Composite floor system Download Scientific Diagram

Related Posts:

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor

- Epoxy Coating On Concrete Floor