Although you may be able to keep the floor war of yours with radiant floor heating fitted, in case you do not have the option as well as concrete flooring generally is a bit cold. Polished concrete floors, long consigned to finished basements as well as industrial spaces, are making well deserved inroads into residential homes.

Images about Concrete Floor Epoxy Crack Filler

Concrete Floor Epoxy Crack Filler

Wet polishing creates waste slurry that effortlessly spreads into hard-to-find difficult to reach locations. On a brand new concrete, stain concrete floor surfaces producers advise letting the concrete solution for no less than a month. Apart from making polished concrete extremely sustainable, concrete has long been the least expensive flooring choice available.

Epoxy Concrete Repair Crack Treatment and Concrete Crack Filler

Bear in mind concrete flooring is usually covered with several substances like epoxy, a lovely sturdy finish that can be used someplace in the home. Concrete office flooring is a green colored choice that usually outlasts various other floor types as linoleum, wood, tile, and carpet.

Concrete crack repair and filler 100% Solid Epoxy Filler

When to call a professional to repair cracked concrete

CRACK REPAIR EPOXY PUTTY

Foundation Crack Repair in 8 Steps – This Old House

Foundation Floor Crack Repair CrackX

How To Apply Concrete Floor Crack Filler Before Epoxy? – Ultimate

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

Liquid Cement Crack Filler DAP Global

Introducing Sika Injectokit TH Concrete Crack Repair System

Epoxy Damaged Concrete Repair Concrete Crack Repair Epoxy Jemkon

Garage Epoxy Flooring Concrete Repair Resurfacing

Epoxy Crack Injection Concrete Repair SealBoss Corp.

Related Posts:

- How To Stain Concrete Floors Outdoors

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor

Introduction to Concrete Floor Epoxy Crack Filler

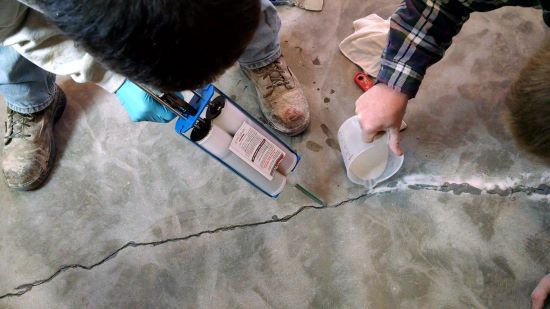

Concrete floor epoxy crack filler is a specialized material used to fill in cracks or gaps in concrete floors that have been damaged due to wear and tear, weather, or other factors. It is an easy-to-use solution for repairing and protecting concrete from future damage. It provides a strong, waterproof seal that prevents moisture from seeping into the surface and causing further damage. It also helps to prevent mold, mildew, and bacteria from growing in the cracks. The epoxy crack filler is designed to adhere tightly to the surface of the concrete, creating a durable barrier that will help to protect and preserve the integrity of your concrete floor.

Benefits of Using Concrete Floor Epoxy Crack Filler

Using concrete floor epoxy crack filler can provide a number of benefits for homeowners or business owners. The epoxy crack filler is designed to create a strong bond with the surface of the concrete, creating a waterproof seal that prevents moisture from seeping into the surface and causing further damage. This helps to protect the underlying structure of the concrete from further deterioration. Additionally, it helps to prevent mold, mildew, and bacteria from growing in the cracks, which can cause health issues for anyone who comes into contact with the affected area. The epoxy crack filler also helps to restore the appearance of the concrete, providing a more aesthetically pleasing look.

How to Apply Concrete Floor Epoxy Crack Filler

Applying concrete floor epoxy crack filler is relatively easy and requires minimal tools and supplies. Before beginning the process, it is important to make sure that all debris and dirt are removed from the cracks so that the epoxy can adhere properly. Once the area is cleaned, you will need to mix the epoxy according to instructions on the packaging. Once mixed, you can apply it directly into the cracks using a caulking gun or putty knife. You will want to make sure that you evenly distribute the epoxy throughout the cracks so that it seals properly. Allow it to dry completely before walking on it.

Maintenance Tips for Concrete Floor Epoxy Crack Filler

Once you have applied concrete floor epoxy crack filler, there are some maintenance tips that you should follow in order to ensure it lasts as long as possible. It is important to keep in mind that this material is not designed for heavy-duty use and should not be used in areas where there will be a lot of foot traffic or heavy equipment moving over it. Additionally, it is important to regularly check for any signs of wear or damage so that any necessary repairs can be made in a timely manner. It is also important to clean the area regularly with a mild soap and water solution in order to prevent any dirt or debris from building up and causing further damage.

FAQs about Concrete Floor Epoxy Crack Filler

Q: Is concrete floor epoxy crack filler difficult to apply?

A: Applying concrete floor epoxy crack filler is relatively easy and requires minimal tools and supplies. Before beginning the process, it is important to make sure that all debris and dirt are removed from the cracks so that the epoxy can adhere properly. Once mixed, you can apply it directly into the cracks using a caulking gun or putty knife. You will want to make sure that you evenly distribute the epoxy throughout the cracks so that it seals properly. Allow it to dry completely before walking on it.

Q: How often should I inspect my concrete floor epoxy crack filler?

A: It is important to regularly check for any signs of wear or damage so that any necessary repairs can be made in a timely manner. It is also important to clean the area regularly with a mild soap and water solution in order to prevent any dirt or debris from building up and causing further damage.

Q: Will concrete floor epoxy crack filler protect my concrete from further damage?

A: Yes, using concrete floor epoxy crack filler can provide protection against further damage by creating a strong bond with the surface of the concrete, creating a waterproof seal that prevents moisture from seeping into the surface and causing further damage. Additionally, it helps to prevent mold, mildew, and bacteria from growing in the cracks which can cause health issues

/cdn.vox-cdn.com/uploads/chorus_asset/file/19495119/00_concrete_xl.jpg)