Benefits of New Concrete Floor Construction

I’ve always been fascinated by construction and home improvement, and recently, I’ve been exploring the advantages of using new concrete floor construction in various projects. It’s incredible how a simple change in the foundation of a space can bring about so many benefits. Let’s find out more about these benefits.

- Durability: One of the primary benefits of new concrete floor construction is its exceptional durability. Concrete floors are known for their strength and can withstand heavy loads and high traffic. They are resistant to wear and tear, making them a long-lasting flooring option.

- Low maintenance: Concrete floors are relatively low maintenance compared to other flooring materials. They are easy to clean and require minimal upkeep. Regular sweeping and occasional mopping are usually sufficient to keep them in good condition. Additionally, concrete floors do not require any special cleaning products or treatments.

- Versatility: New concrete floor construction offers a wide range of design possibilities, allowing for customization to suit various aesthetic preferences. Concrete can be stained, polished, or textured to create different looks and finishes. It can also be stamped or engraved with patterns or logos, making it a versatile flooring choice for both residential and commercial spaces.

- Cost-effective: Concrete floors are cost-effective in the long run. While the initial installation cost may be higher compared to some other flooring options, the long lifespan and low maintenance requirements compensate for the upfront investment. Additionally, concrete floors can provide energy-saving benefits by retaining and releasing heat, reducing heating and cooling expenses.

- Sustainability: Concrete is an eco-friendly and sustainable material. It is made from natural resources such as sand, gravel, and water, and does not deplete non-renewable resources. Concrete floors also have a high thermal mass, which helps regulate indoor temperature, reducing the need for artificial heating or cooling. Furthermore, concrete can be recycled and reused, making it a sustainable choice for flooring construction.

- Improved indoor air quality: New concrete floor construction can contribute to better indoor air quality. Unlike some flooring materials that may trap allergens, concrete floors do not harbor dust mites, pet dander, or other allergens. They are also resistant to mold and mildew growth, improving the overall air quality in the space.

- Enhanced safety: Concrete floors offer excellent slip resistance, especially when treated with a non-slip sealer or coating. This feature makes them a safe choice for areas prone to moisture, such as kitchens, bathrooms, and entryways. Concrete floors also have a high fire resistance rating, providing an added safety benefit.

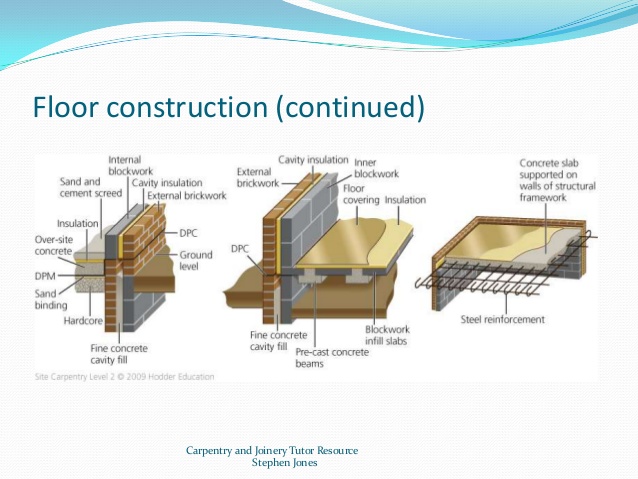

Steps to Achieve a High-Quality Concrete Floor

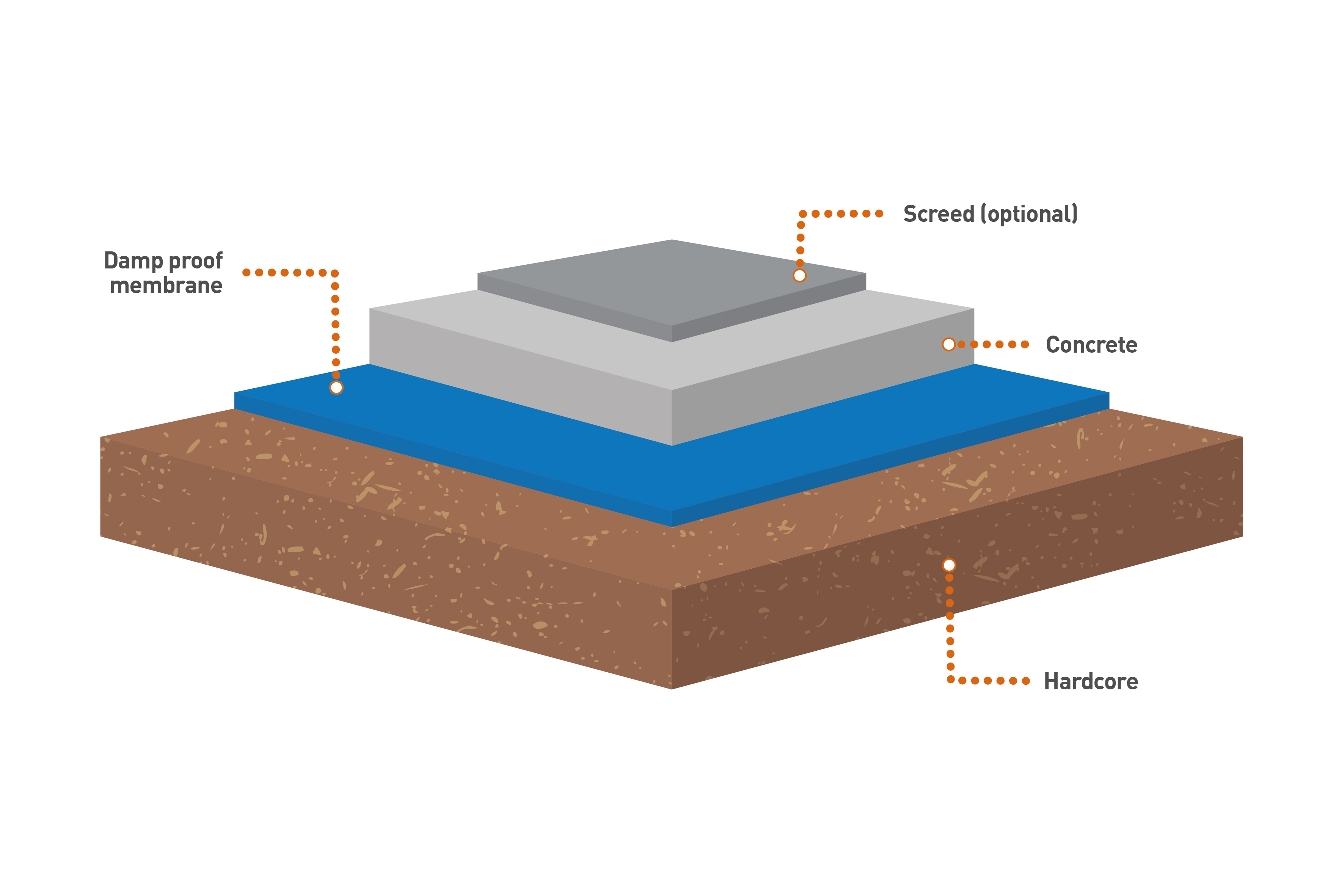

1. Site Preparation:

Before starting the construction of a new concrete floor, proper site preparation is crucial. This involves clearing the area of any debris, vegetation, or existing flooring materials. The ground should be leveled and compacted to ensure a stable base for the concrete.

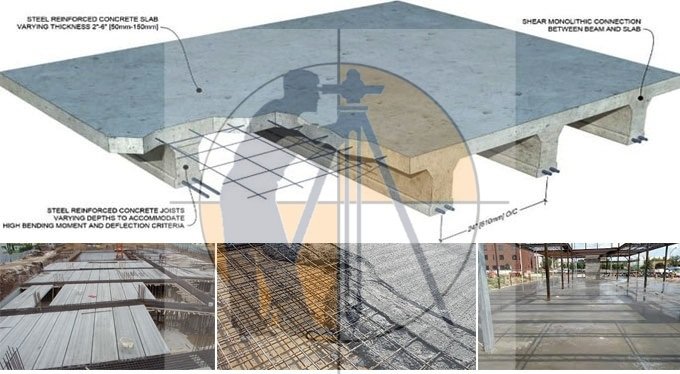

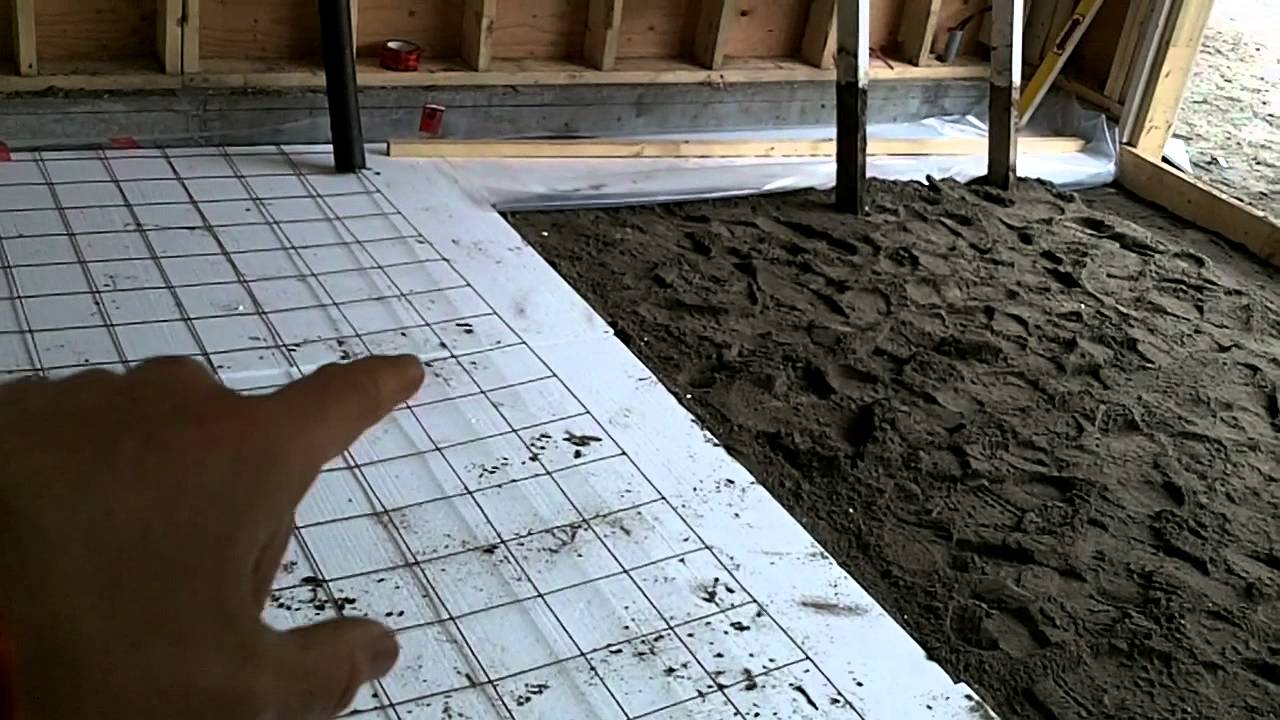

2. Reinforcement Installation:

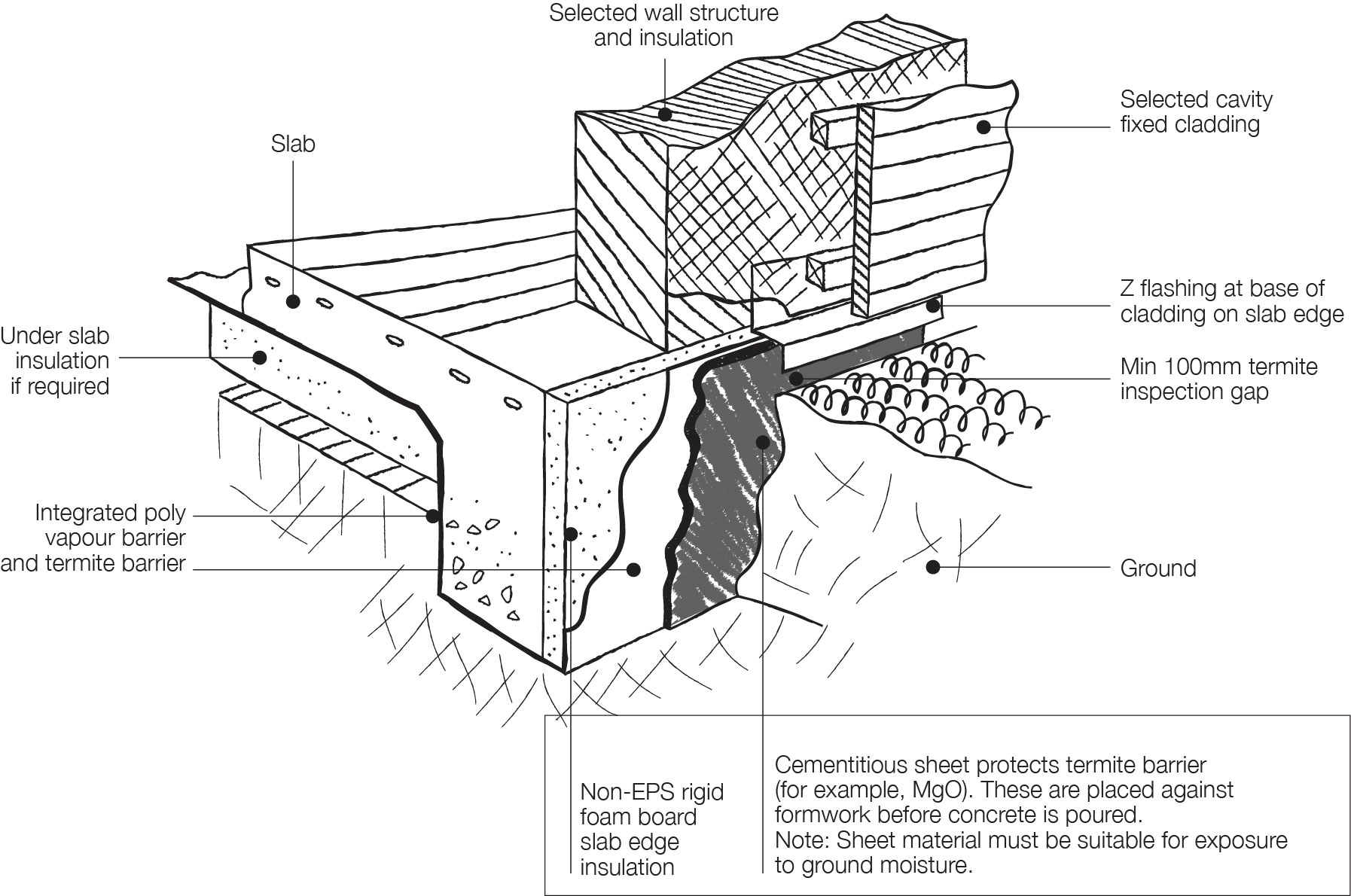

To enhance the strength and durability of the concrete floor, reinforcement materials such as steel bars or mesh are often used. These reinforcements help to distribute the load evenly and prevent cracking or sinking over time. They should be placed according to the design specifications and securely tied together.

3. Formwork Construction:

Formwork is the temporary structure that holds the concrete in place until it dries and hardens. It is essential to construct sturdy and accurate formwork to achieve a level and smooth concrete surface. The formwork should be properly aligned, braced, and sealed to prevent leakage.

4. Mixing and Pouring the Concrete:

The quality of the concrete mixture is crucial in achieving a high-quality concrete floor. The correct proportions of cement, aggregates, water, and admixtures should be measured accurately and mixed thoroughly. The concrete should be poured evenly and without interruption to ensure uniformity and avoid weak spots.

5. Finishing Techniques:

Once the concrete has been poured, various finishing techniques can be applied to achieve a smooth and aesthetically pleasing surface. These techniques include floating, troweling, and brooming. Floating is done using a tool to level and smooth the concrete, while troweling helps to create a polished finish. Brooming is commonly used for outdoor concrete surfaces to provide texture and prevent slipping.

6. Curing and Protection:

Proper curing is essential to allow the concrete to reach its maximum strength and durability. Curing involves keeping the concrete moist and at a favorable temperature for a specified period. This can be achieved through methods such as wet curing, using curing compounds, or covering the concrete with plastic sheets. Additionally, the newly constructed concrete floor should be protected from heavy traffic or other potential damage during the curing process.

7. Regular Maintenance:

To ensure the long-term durability and appearance of the concrete floor, regular maintenance is necessary. This includes cleaning the surface regularly to remove dirt and debris, promptly repairing any cracks or damages, and applying sealants or coatings as needed to protect the concrete from moisture and wear.

Choosing the Right Materials for New Concrete Floor Construction

When embarking on a new concrete floor construction project, it is crucial to choose the right materials to ensure the longevity, durability, and overall quality of the floor. The materials selected will depend on various factors such as the intended use of the floor, the desired aesthetic, and the budget.

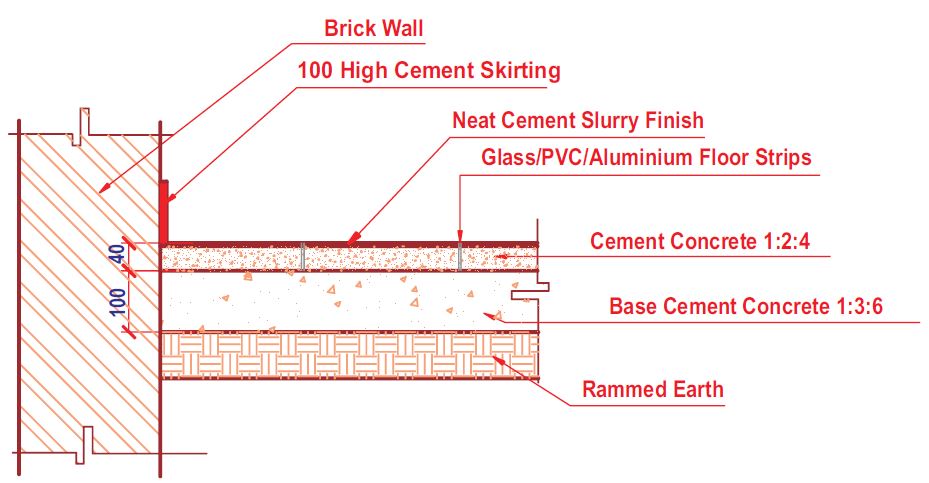

One of the key materials to consider is the concrete mix itself. The type of concrete mix used will determine the strength and durability of the floor. There are different types of concrete mixes available, such as regular concrete, high-strength concrete, and self-consolidating concrete. The choice of concrete mix will depend on factors such as the load-bearing capacity required and the expected traffic on the floor.

In addition to the concrete mix, the right aggregates should be selected to enhance the performance of the concrete floor. Aggregates, such as sand, gravel, and crushed stone, provide bulk to the concrete and contribute to its strength and durability. The size and shape of the aggregates can also affect the workability and finish of the floor.

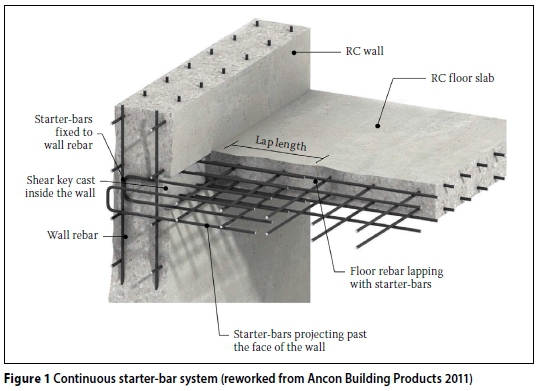

Another important consideration is the reinforcement materials. Reinforcing the concrete with materials such as steel bars or fibers can significantly increase the strength and resistance of the floor. The choice of reinforcement materials will depend on factors such as the expected load on the floor and the level of protection required against cracking or deformation.

Furthermore, the selection of the right admixtures is crucial in achieving specific properties or performance characteristics for the concrete floor. Admixtures are added to the concrete mix to enhance workability, reduce water content, improve strength, or provide other desired properties. Examples of common admixtures include water reducers, accelerators, retarders, and air-entraining agents. The choice of admixtures will depend on the specific requirements of the project.

Last, the choice of finishing materials is essential for achieving the desired aesthetic and functional qualities of the concrete floor. Finishing materials such as sealers, coatings, or toppings can enhance the appearance, protect against stains or abrasion, and improve the overall performance of the floor. The selection of finishing materials will depend on factors such as the desired level of gloss, the expected foot or vehicular traffic, and the maintenance requirements.

Common Mistakes to Avoid During Concrete Floor Construction

Poor Site Preparation: One of the most common mistakes in new concrete floor construction is inadequate site preparation. It is crucial to ensure that the ground is properly leveled and compacted before pouring concrete. Failure to do so can result in uneven surfaces, cracks, and other structural issues.

Inaccurate Measurements: Accurate measurements are essential for a successful concrete floor construction project. Mistakes in measuring and marking out the area can lead to uneven thickness or improper alignment of the concrete. It is vital to double-check all measurements to avoid costly and time-consuming errors.

Insufficient Reinforcement: Reinforcement plays a vital role in the strength and durability of concrete floors. Neglecting to include the appropriate amount of reinforcement, such as steel bars or fibers, can weaken the structure and increase the risk of cracking and collapsing. It is crucial to follow engineering specifications and guidelines to ensure proper reinforcement.

Improper Mixing and Placement: The quality of the concrete mix and its proper placement are critical factors in achieving a durable and long-lasting concrete floor. Common mistakes include using incorrect water-to-cement ratios, improper mixing techniques, and inadequate consolidation during placement. These errors can result in weak concrete, cracking, and poor overall performance.

Inadequate Curing and Moisture Control: Curing is the process of maintaining the moisture content in the concrete for a specific period to allow it to gain strength and durability. Neglecting proper curing can result in weak concrete, decreased durability, and increased susceptibility to cracking. Additionally, inadequate moisture control during the curing process can lead to shrinkage and curling of the concrete floor.

Ignoring Expansion and Contraction Joints: Concrete naturally expands and contracts with temperature changes. Ignoring the inclusion of expansion and contraction joints can result in unsightly and potentially damaging cracks. These joints allow the concrete to move without causing stress and structural damage. It is important to include these joints at the appropriate intervals as specified by construction standards.

Neglecting Proper Finishing Techniques: Proper finishing techniques are essential for achieving a smooth, even, and aesthetically pleasing concrete floor. Common mistakes include overworking the surface, inadequate floating or troweling, and improper use of curing compounds. These mistakes can result in an uneven surface, premature wear, and a decrease in the overall appearance and performance of the floor.

Garage Build Part 13 – Preparing the floor to pour concrete

PDH Quiz – Guide for Concrete Floor and Slab Construction

Alternative wall-to-slab connection systems in reinforced concrete

Concrete slab floor construction BRANZ Renovate

HOW TO CONSTRUCT CEMENT CONCRETE FLOOR? – CivilBlog.Org

Floors – Types of floors – Methods of Construction of Floor

Building Guidelines Concrete Floors, Slabs

Minimizing Concrete in a Slab-on-Grade Home – Fine Homebuilding

Concrete slab floors YourHome

Related Posts:

- DIY Stained Concrete Floors In Homes

- Concrete Floors Look Like Marble

- Concrete Floor Slab Mix Ratio

- Dark Brown Concrete Floor Paint

- Pretty Concrete Floors

- Stained Concrete Floors For Homes

- Decorative Concrete Floor Ideas

- Pouring A Concrete Floor In A Garage

- How To Get Smooth Concrete Floor

- Epoxy Coating On Concrete Floor